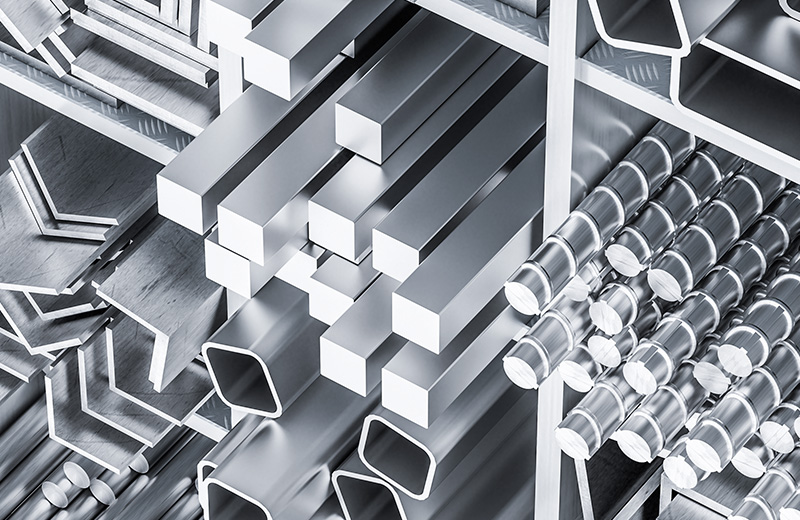

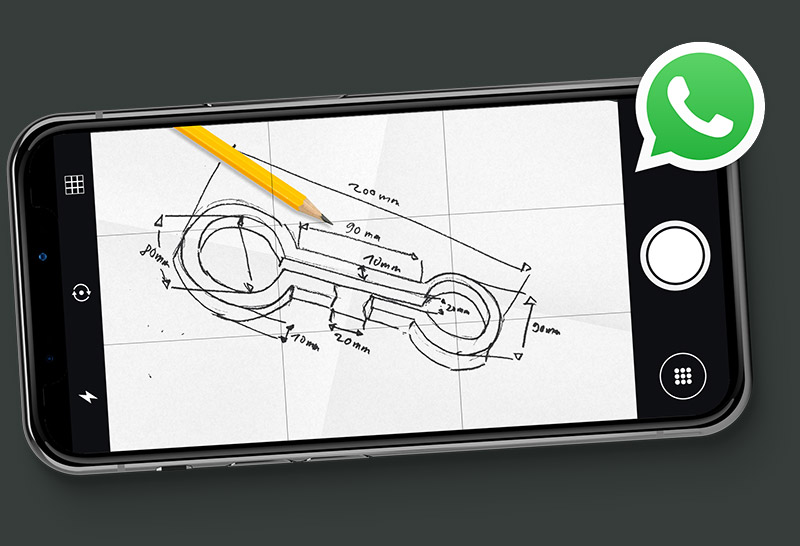

sheets, plates, profiles, blanks or milled parts?

Steel semi-finished

CK 45 (C45E o. C45W) 1.1191 o. 1.1730

Batz + Burgel has been a competent partner of the industry in the field of metal trade and metalworking for more than 25 years.

A wide range of products, our high manufacturing competence, from single parts to pre-assembly of complex assemblies, as well as fast and flexible response characterize our company.