1. Chemical composition

| C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Other elements |

| 0,2 |

0,55 |

1,6 |

0,035 |

0,035 |

- |

- |

- |

|

2. mechanical properties

| Condition |

Nominal thickness |

Tensile strength |

Plug-in.limit |

Ultimate elongation |

Rigor |

|

in mm |

Rm in MPa |

Rp0,2 in MPa |

in % (min.) |

HBS |

| over |

over |

up to |

min |

max |

min |

max |

A50 |

A |

|

| grounded |

5 |

60 |

450 |

630 |

295 |

355 |

18-22 |

- |

- |

|

|

General properties |

| (Guide values for 20° C) |

|

| Density of g/cm3 |

7,85 |

Special annealing |

- |

| Thermal conductivity W/(mK |

35-45 |

Workability |

2 |

| Modulus of elasticity kN/mm2 |

|

Dimensional stability |

|

| Therm. linear expansion- |

|

Weldability |

4 |

| Coeffizient 10-6/K |

11-14 |

Corrosion resistance |

5 |

|

|

Acid resistance |

5 |

| Standard tolerances |

|

Surface treatment |

|

| Surface quality Ra |

1,6 |

Hardening |

4 |

| Thickness tolerance mm |

+0,3/-0 |

Nickel-plating |

2 |

| Length and width tolerance mm |

-0/+2 |

|

|

| Parallelism mm |

<0,1 |

|

|

| Flatness mm |

<0,5 |

|

|

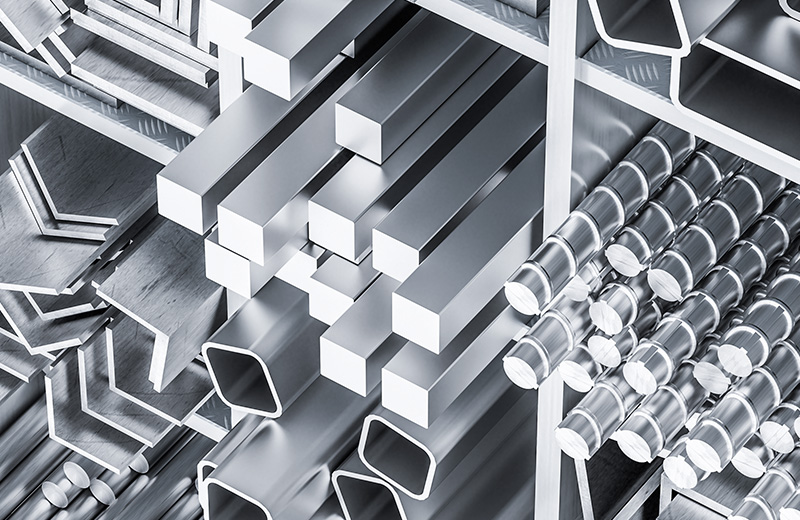

3. Type:

material normalized, thickness ground, length and width sawn or plasma cut

Against surcharge: Outside contour milled with tolerance of +/-0.2 mm

4. Main application / Special features:

Base plate, table plate, mounting plate, cladding plates